Service Introduction

Your Location:Home | Consulting Service | Service Introduction

ASCMS Consultancy Service Background

|

Key Factors

|

Exposures

|

|

Business response

|

Supply chain functional response lags customer needs; it needs to be reengineered for optimization

|

|

Supply & demand balancing

|

Obvious unbalancing between supply and demand, huge waste of resources

|

|

Completed business process

|

Uncompleted & low synthesis among functional business processes, high total cost with no efficiency leverage

|

|

Resource synthesis

|

No service integration among groups,no centralized management cross different functions and resources

|

|

KPI & continuous improvement

|

Key performance indicator management does not support business strategy; lacks of continuous improvement for competitiveness

|

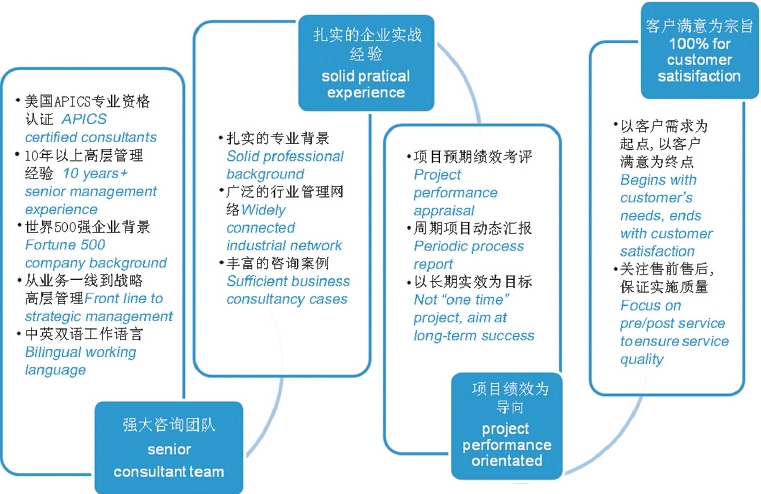

ASCMS Consultancy Service Competitive Advantage

ASCMS Consultancy Service Values

★To build core competitive advantages for company’s operation management and manufacturing strategy, to support effective business execution.

★To improve customer satisfaction,by redesign material planning and control system, reduce manufacturing cost and cycle time for a more reliable and flexible delivery service.

★To instruct process optimization by establishing the business process oriented management system for less risks exposures but a lean organization with less waste and better efficiency.

★To set a customer focused performance scorecard system, to encourage synthesis among inter companies and related companies, keep continuous promotion on company’s core competitive advantage.

★To set career path, succession plan and performance appraisal system for an overall team performance improvement and stronger business loyalty.

Supply chain operation management consultancy series

The serial is designed to help the company to systemically diagnose related operational issues in Supply Chain Management in order to propose related solutions to meet expectations of operational performance.

Most popular consulting services

★Lauch and improvement of S&OP

★Lauch and improvement of MPS

★Concept design of warehouse center

Supply Chain Continuous Improvement Serial

The serial is designed to help the company on supply chain continuous improvement. It’s designed to set a more effective performance measurement, to practice lean thinking for less waste, to optimize resource allocation and long term organizational strategic management for a more competitive performance.

24H Supply chain workshop program

24H practical supply chain workshop consultancy service is specially designed based upon ASCMS’s strong training capability and quick SCM problem solving skills. It’s widely welcomed by small or medium sized company. The whole consultancy service aims to be completed in 3 full working days, it combines consultancy and training, has relatively low investment and is more practical for onsite problem solving.

The service is designed as:

1st day, data collection, problem diagnosis and initial proposal.

2nd day, running trial of improvement proposal, collecting implementation feedback and document related process.

3rd day, provide training and improvement process conclusion.

Detailed scenario could be adjusted upon customer’s actual needs and different business cases.