Consulting Service on the Launch and Improvement of Sales and Operations Planning (S&OP) system

Key Contents of S&OP Launch and Improvement Service

More and more well-known management philosophies like TQM, ERP, Lean, 6Sigma, and CRM have been widely deployed by the enterprises. But are you quite often frustrated by the following questions:

★ CEO or president: How do we effectively and easily visualize the interactions between the enterprise-level Business Plan (from financial perspective) and the market trends, actual sales performances, internal operation performance, and assets utilization like inventory? Meanwhile, how do we tie the Business Plan which reflects the expectations of financial returns, to product series, families, subfamilies, models or even part numbers? The Business Plan should be able to adapt to the dynamic sales and operations status. We also need to know how to integrate the Business Plan with the product life cycle management activities including product planning, development and introduction to the market.

★ VP for Sales and Marketing: The market is hot, the demand is huge. But why do we often delay the customers’ orders? We are damaging our credibility with the customers and the motivations of our sales people. Why do we need so much market promotion to sell out the stock with very low prices which won’t bring our sales people reasonable rewards either mentally or financially? We have no clear clue about how to link Sale ans Marketing to the new product development progresses, not to mention how to allocate the sales targets of new products to the individual customers.

★ VP for Production: I am crazy with my WIP and FGI (finished goods inventory). The production rates are changing so randomly due to the unexpected sales orders or shortage of material supply. We can hardly plan the capacity in advance. Changeover is not under control, and the workers morale is low. I am seeing unreasonable operation costs.

★ VP for Supply Chain and Sourcing: We just don’t have the needed trust from our suppliers on our material requirement forecast. There are many supply shortages. We are in a relatively weak negotiating position with suppliers on prices because we always ask for the help from them to handle our emergent purchase orders. We don’t have information about our new product development strategy and progress which prevents us from sourcing the best suppliers and materials. Material quality performance? How can we be accountable for it if we don’t have a validation process completed for the new materials. We will likely see a big loss from the obsolescence disposal.

★ VP for Finance: Inventory values are soaring and out of control. I am concerned of the great risks of cash flow. There is no consistent “one set of numbers” between the Business Plan and the rolling forecast of the sales and profit expectation. How can I view the whole dynamic picture from 5,000 feet above?

★ VP for Product Development: It seems to me that there should be a clear schedule for the new product introduction to the market. I cannot find this kind of information from the rolling sales forecast or production plan. I need my engineers to be fully prepared to get the feedback from internal and external customers so that they can do the necessary improvements on the quality, functions, appearance and design. I also have no idea if the production capacity is ready for a new product.

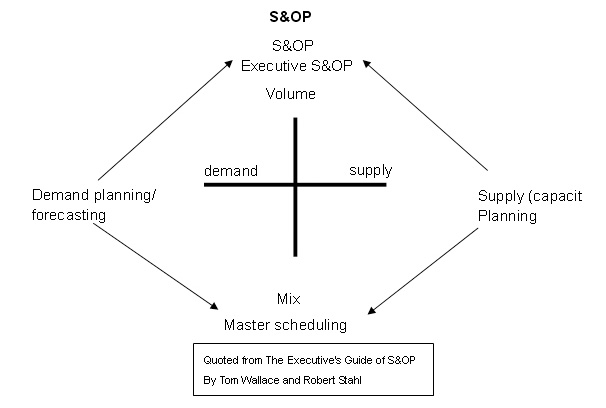

It is proven that there must be a planning process between the enterprise-level Business Plan and the production scheduling. The planning process is Sales and Operations Planning (S&OP). This practice has been widely implemented globally for a limited investment and significant results.

S&OP is a set of decision-making processes with three main objectives:

★ To balance demand and supply

★ To align volume an mix

★ To integrate operational plans with financial plans

Benefits resulting from effective Sales & Operations Planning (S&OP) include:

1. For Make-to-Stock companies: higher customer service and often lower finished goods inventories – at the same time.

2. For Make-to-Order companies: higher customer service, and often smaller customer order backlogs and hence shorter lead times – at the same time.

3. For Finish-to Order/Postponement companies: higher customer service, quicker response, and often lower component inventories – at the same time.

4. More stable production rates and less overtime, leading to higher productivity.

5. Better visibility into future capacity problems, both too much work and too little.

6. Enhanced teamwork among the middle-management people from Sales, Operations, Finance and Production Development.

7. Enhanced teamwork within the executive group.

8. Greater accountability regarding actual performance to plan.

9. A better demand/supply balance across the company’s supply chain.

10. A monthly update to the Business Plan, leading to better forward visibility and fewer surprises late in the fiscal year.

11. The establishment of “one set of numbers” with which to run the business. The primary functional areas of the business – Sales/Marketing, Operations, Finance, Product Development, and General Management – all operate with a common game plan.

12. The ability to make changes quickly off of that common game plan.

13. A sharp decrease in the amount of detailed forecasting and scheduling required, because the volume plans in S&OP eliminate the need for detailed mix plans extending far into the future.

14. Last and certainly not least, S&OP provides as we said a “window into the future”. It’s uncanny but the process – when done well – truly does enable people to better see future problems coming at them: a large increase in workload several months out, an upcoming new product launch that will consume substantial plant capacity, a forecasted downturn in demand later in the year. S&OP enhances proactive decision-making.

Relevant Training and Consulting Service on S&OP

Allied Suppliy Chain Management Solutions (ASCMS) is the first education and consulting organization in China which introduced the APICS body of knowledge about operations and supply chain management. In the past years, ASCMS has developed its resources including the body of knowledge from APICS, collaborations with Tom Wallace and IBF, the professional intelligence contributed by the managers from the MNC’s who are dedicated to the operations management arena and leading the S&OP process. Many leading MNC’s in the various industries like automotive, heavy equipment, chemical manufacture, pharmaceutical, electronics, IT, food and beverage, retailing and distribution have been served by ASCMS in terms of training and consulting. ASCMS will be your good partner to launch and improve the S&OP in a tailored way.

Key Contents of Launch and Improvement of S&OP

1. Roadmap development for S&OP

★ The relationship between S&OP and enterprise business strategy

★ The integration between S&OP and other management tools like ERP, supply chain management and operations management

★ S&OP in the different business models like MTS, MTO and FTO

2. Key steps of S&OP process

★ Data gathering

★ The demand planning phase

★ The supply (capacity) planning phase

★ The pre-S&OP meeting

★ The executive S&OP meeting

3. The implementation of S&OP

★ Preparation for the implementation

★ Data preparation

★ Spreadsheets and tools development

★ Pilot one or two families

★ Develop S&OP policy

★ Bring all families and continue the improvement

★ Multiple-site, multi-business S&OP

★ S&OP and supplier collaboration